Saying YES to the 5S Method to Boost Efficiency at Work

The new year starts with the best intentions. Yet, many resolutions fall apart in just a few short weeks. Serious changes require a serious mindset. Sometimes, it’s just getting back to the basics. I you’re an employer, there are ways to get back to basics and make some changes for the better that can dramatically improve your business.

Many manufacturing and warehouse operations utilize a system called 5S. But this system can be used in any workplace situation, office, and even personally to improve private lives.

- seiri (整理)

- seiton (整頓)

- seisō (清掃)

- seiketsu (清潔)

- shitsuke (躾)

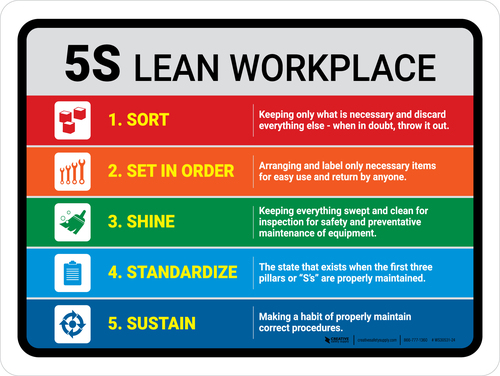

These words are translated respectively to “sort”, “set in order”, “shine”, “standardize”, and “sustain”. Whether this is the first you’ve heard of 5S, you already incorporate it somewhat or wholly into your business, or you’ve strayed from the principles over time to keep up with demand, turnover, or inflation, the new year is a great time to relaunch these initiatives. The 5S methodologies have helped millions of companies eliminate waste and improve efficiencies. The history of 5S goes back as far as the 16th Century to Venice shipbuilders where a streamlined assembly process helped workers build ships in a very short amount of time. Modern origins of 5S originated with Japanese inventor Sakichi Toyoda–the founder of Toyota who is also known as the “father of the Japanese industrial revolution.”

5S is a workplace organization method that incorporate five Japanese words:

A sixth S is frequently added: safe.

Here’s a brief explanation of each element of the 5S’s.

seiri (整理) | Sort

The main focus of sort, the anchor of the 5S, is get rid of all the things you don’t need. Get rid of clutter and tools and materials that impede workflow, eliminate unnecessary clutter, and inventory. Sometimes the clutter has just become part of the scenery. The bonus is that you’ve eliminated distractions and made the workplace cleaner and safer. If you’re not using something daily or weekly, it might be time to sort it out to the bin or holding area. Many suggest this is the most aggressive area to tackle. Be diligent in keeping out only tools and materials needed. Doing this correctly helps make the other elements of the 5S’s flow much easier.

seiton (整頓) | Set in Order

Now that you’ve only got essential items in the work area needed, each item needs its place. The idea is to make it as readily available when it is needed. Using clearly marked labels, pictures, and printed materials will help individuals adhere to this principle. Make sure all items are returned upon use to their proper place.

seisō (清掃) | Shine

A clean workspace is an efficient workspace. This is not just lack of clutter and having an organized space, it’s actually about cleaning. Wiping things down, sweeping, mopping, and even lubrication of parts and machines. Think about how a restaurant leaves the kitchen (you’d hope) at the end of the night: as close to brand new for the next operator. An added benefit of “shine” is that the added pride for the workforce.

seiketsu (清潔) | Standardize

Everything should be done the same by everyone, every time. By getting rid of variations, you can reduce the risks of errors, the amount of time a task takes, and drastically reduce defects. People will naturally try to find shortcuts, or workarounds, or a more comfortable way to perform a task. This can be a difficult part of the 5S to implement and can require the most attention. Efficiency and precision are the fundamentals of the Standardize function of 5S.

shitsuke (躾) | Sustain

As with all resolutions, this one can be the most difficult to accomplish. To make change, it requires a sustained and consistent effort, until it becomes a habit and workplace culture. Sustain means to take all of the previous functions of the 5S and continually monitor, update, and improve upon them. The sustain function of the 5S is to ensure that your hard work lasts for the long-term.

Whether 5S has been a mainstay of your industry and in operation for decades, or the concept is new to your business, these are simple practices as the new year begins that can drastically improve the efficiency and output of your business. Happy New Year from WSI.