Remember when a weekend shift or entry-level gig got you into manufacturing? That ladder’s breaking. AI isn’t just nibbling at white-collar internships—it’s devouring the grunt-work jobs many plants rely on. As someone who’s seen hiring seasons come and go, I’m calling it: employers and Gen Z need a new playbook.

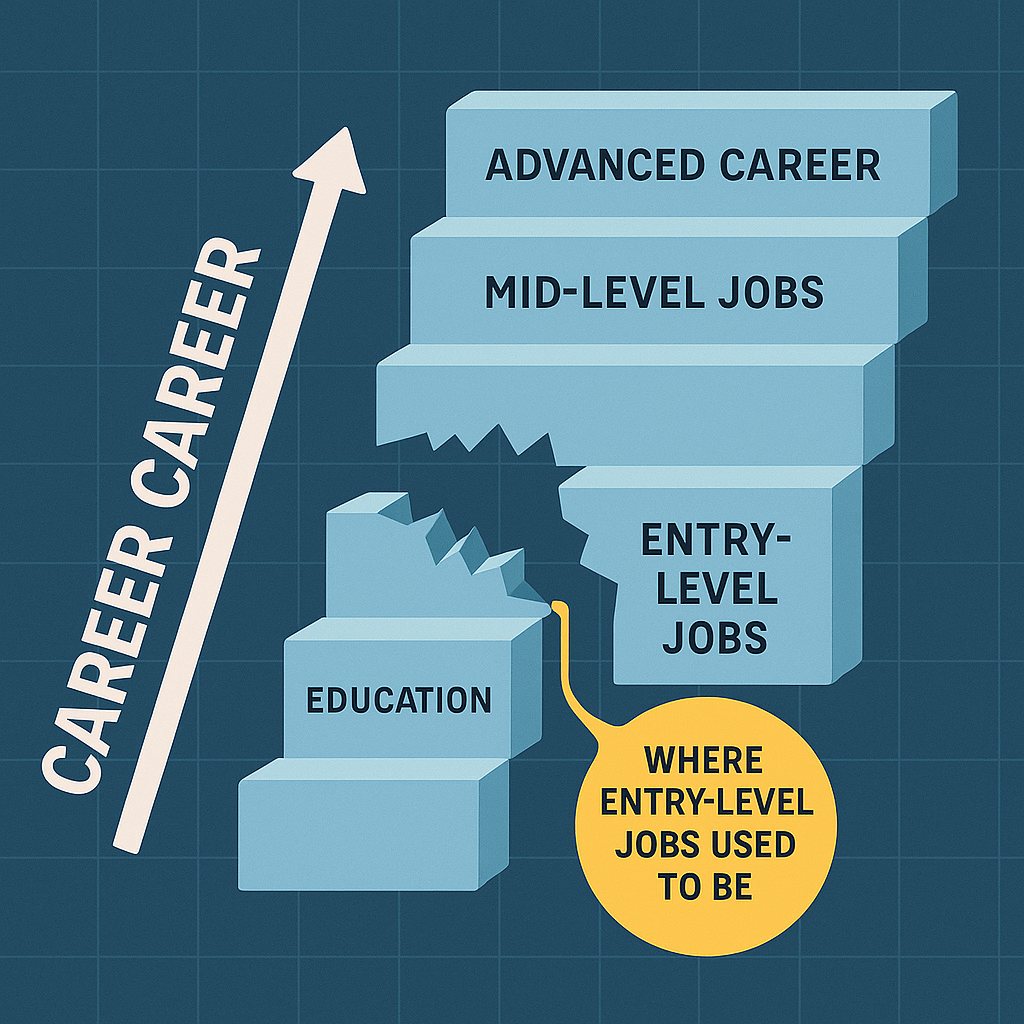

AI is automating routine roles—from first-year clerks to warehouse packers—creating fewer chances to gain experience. As the NY Post warns, “traditional entry-level jobs … are either disappearing or transforming beyond recognition.” Even Fortune recently described it as a breaking point: AI is “breaking” entry-level jobs that Gen Z workers need to launch careers. That means fewer openings for those stepping in at the ground floor—even in manufacturing, where entry gigs once ruled.

Factories and assembly lines historically fed young workers with real-world learning. But automated warehouses, cobots, and forklifts driven by AI are pushing humans out. Websites like Indeed already show thousands of listings for AI-driven roles—shift supervisors to robotics project managers—but few frontline operator positions. It’s a structural shift. We’re not just losing jobs; we’re losing the training paths that prepared people to climb to technical or management roles.

Skimping on early-career jobs means fewer future engineers or supervisors—and Michigan feels this. A Washington Post forum on U.S. manufacturing urged investment in retraining and high-skill immigration. But retraining only matters if there’s a workforce pipeline to build on.

Sure, Gen Z is digitally fluent—76% have used AI tools and more than half use them weekly. That puts them ahead. But AI alone won’t teach leadership, critical thinking, or shop-floor smarts. Experts suggest the future lies in hybrid models: apprenticeship programs that pair humans with AI, creating “AI-assisted apprenticeships and hybrid human-AI teams.” Good plan—but who’s stepping up to fund them?

Manufacturing employers need to rethink their approach now. Resist the urge to eliminate all entry-level jobs. Instead, redesign them. Create roles that teach both AI tools and mechanical basics. Upskill your workforce by investing in online courses or community-college partnerships. Offer “AI + mechanical” training tracks—think automation technicians or digital-twin operators. And build actual ladder paths. Entry-level positions should map to technical and supervisory roles, not dead ends. Michigan and other regions invested in reshoring should consider this strategic.

Lastly, partner with schools. Encourage vocational programs to include AI in automotive, food-processing, and logistics training. These kids already know how to use the tools. Let’s give them a reason to stay in the industry.

AI isn’t the enemy—it’s the spark. But if we don’t rebuild training ladders, we risk a two-tiered workforce: a few AI-literate engineers and a lost middle class. For manufacturers, the challenge and opportunity lie in redefining entry-level roles, investing in hybrid apprenticeships, and planting seeds for future leadership. Let’s not let tech break the ladder before we’ve built the next one.