Employee Appreciation Day reminds manufacturing leaders that real recognition, respect, and opportunity drive retention more than pizza ever could.

Continue readingWhat 60% of Gen Z’s Career Plans Mean for the Future of Manufacturing

Gen Z is turning toward skilled trades for stability, pay, and AI-proof careers—manufacturers must modernize recruiting to win them.

Continue readingTurning Your Employees Into Brand Ambassadors

Turn shop-floor credibility into a recruiting engine: build a real EVP, fix candidate experience, enable ambassadors, measure outcomes that matter.

Continue readingAI Dashboard Magic Webinar

SNAP on Hold. Why Factories Will Feel It First

Two factory workers in hi vis jackets stand in a staggered line facing a mobile food pantry truck at dusk, watching the volunteer inside as warm light spills onto the cold factory lot.

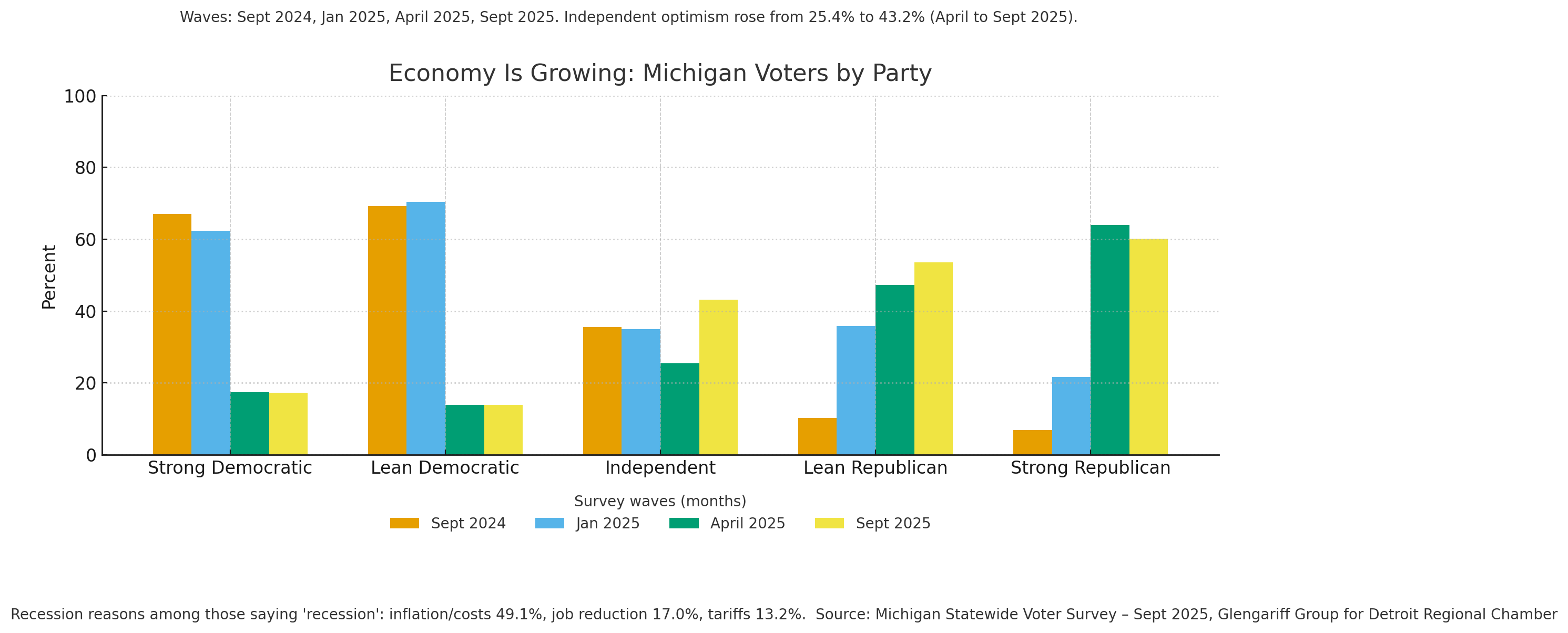

Continue readingMichigan Economy 2025: The Split No One Wants to Admit

Michigan Economy 4Q Outlook 2025: Shutdown Adds New Headwinds

Federal shutdown stalls permits, freezes loans, hits tourism and auto supply chains, eroding confidence across Michigan manufacturers, consumers, and businesses.

Continue readingMichigan Workers Called Lazy in New Survey—But the Numbers Don’t Add Up

WalletHub labeled Michigan the “laziest workforce.” In reality, it’s clickbait—confusing balance with laziness to spark outrage and comments.

Continue readingFrom Biscuits to Backlash: How Cracker Barrel Got Its Rebrand Wrong

Cracker Barrel isn’t often in the headlines. For decades the chain has been a dependable highway stop for biscuits, rocking chairs, and nostalgia. That quiet brand stability shattered in August when the company unveiled a new minimalist logo, stripping away its signature image of an old man leaning on a barrel. The intent was clear. Executives wanted to modernize a brand often tagged as outdated and broaden its appeal to younger diners. The result was anything but.

Continue readingMichigan’s Workforce on the Edge and the Employer Strategies That Work

Discover how Michigan employers tackle workforce hardship with living wages, flexible schedules, and emergency savings to boost retention and engagement.

Continue reading