Four Battle Creek employers were celebrated for pioneering in Registered Apprenticeship Programs. Recognized at Kellogg Community College, these firms exemplify effective workforce training, aligning with Michigan’s strategy to bolster the local talent pipeline and support skilled labor development. This initiative is part of a broader effort to upskill Michigan’s workforce.

Continue readingLack of Labor: Can America Fill Its Factories?

As Michigan experiences a significant resurgence in manufacturing jobs, factory leaders and HR professionals are at a pivotal crossroads. The challenge? Addressing the stark workforce gap that threatens to slow this industrial reawakening.

Continue readingA Shift in Strategy: Ford’s Revised Commitment to the Marshall EV Plant

In late September, Ford Motor Co. made the decision to pause operations at the BlueOval Battery Park in Marshall, Michigan, amidst a UAW strike, raising concerns and expectations among stakeholders. This move, while temporary, hinted at the complex labor dynamics in the automotive industry, particularly in the evolving electric vehicle (EV) sector. Initially, Ford’s investment in the Marshall Megasite was seen as a significant step towards achieving ‘battery independence’ for the U.S. and tripling EV production by 2026. The site promised substantial economic benefits, injecting $3.5 billion into the local economy and creating 2,500 jobs.

However, the recent announcement of Ford scaling back its commitment to the Marshall plant marks a significant shift. The revised plan entails a reduction of 800 jobs and a cut in investment by over $1 billion. This reduction translates to a 40% decrease in the plant’s production capacity, aligning Ford’s strategy with the current pace of EV market growth. Despite these changes, Ford intends to open the plant by 2026 and has resumed work at the site after a two-month hiatus.

The scaling back of the Marshall plant has led to mixed reactions. While some see it as a pragmatic response to market conditions, others view it as a setback for Michigan’s economic development and the EV industry. Mark Truby, a Ford spokesperson, emphasized the company’s continued commitment to EVs but acknowledged the slower growth rate than anticipated. Stacey LaRouche, press secretary for Gov. Gretchen Whitmer, highlighted the positive aspect of bringing 1,700 jobs and significant investment to Michigan, despite the scale-back.

The UAW strike involving Detroit’s ‘Big Three’ automakers played a critical role in shaping the labor dynamics around the Marshall project. The strike’s timing coincided with Ford’s decision-making process for the plant, suggesting an interplay between labor negotiations and strategic corporate decisions. Importantly, the 2023 UAW strike brought to the forefront issues of worker protections in the EV sector. The negotiations likely influenced Ford’s approach, ensuring that the evolving EV industry also addresses workers’ rights and safety, a crucial aspect as the automotive sector transitions to new technologies and production methods.

Ford’s strategic decision to resume work at the Marshall site reflects its commitment to adapt to market conditions and balance investment with demand. The company now expects the facility to produce 20 gigawatt hours of batteries annually, sufficient for about 230,000 vehicles, a reduction from the previously anticipated 35 gigawatt hours. This recalibration is in response to slower-than-expected growth in EV adoption and a disciplined approach to capital allocation.

The scaling back of the project has implications for the state’s subsidy package, initially around $1.8 billion, with adjustments expected in line with Ford’s reduced investment. While some local residents and environmental groups have expressed concerns, the project continues to be a key piece in Michigan’s strategy to revitalize communities and foster key industries for the state’s future.

Ford’s Marshall EV battery plant represents more than just an industrial project; it is a microcosm of the broader challenges and opportunities in the transition to electric vehicles. As the automotive industry navigates this transformation, balancing market demands, labor dynamics, and community impacts will be crucial. The evolving situation at the Marshall plant illustrates the need for adaptive strategies and collaborative efforts to ensure that the shift towards sustainable transportation benefits all stakeholders involved.

Unemployment Insurance Fraud: A Drain On Us All.

As we observe Fraud Awareness Week, it’s crucial to shine a spotlight on the ongoing battle against Unemployment Insurance (UI) fraud and the dedicated efforts of teams like ours at WSI Recruitment and Staffing in safeguarding the integrity of the labor market

In the ever-changing landscape of employment, Unemployment Insurance (UI) fraud poses a significant challenge, affecting not just the state funds but also the integrity of businesses and the welfare of legitimate claimants. This week, we’re taking a moment to highlight and celebrate the tireless efforts of our WSI Recruitment and Staffing Risk team, who play a crucial role in investigating claims and preventing UI fraud, thus helping keep taxes and government waste down, ensuring our business stays competitive, and safeguarding our clients from fraudulent claims.

Understanding UI Fraud

UI Fraud is a serious offense that involves individuals misrepresenting information to claim unemployment benefits unlawfully. This deception can take many forms, from claimants working while collecting benefits without reporting earnings, to employers misclassifying employees to evade taxes. The consequences are far-reaching, increasing unemployment taxes for businesses, burdening legitimate claimants, and straining the state’s unemployment funds.

Our Response to UI Fraud

At WSI Recruitment and Staffing, our dedicated Risk team members, Jade and Suzette, are constantly vigilant, employing strategies to detect and prevent such fraudulent activities. By staying informed about the latest fraud trends, diligently investigating all unemployment claims and injuries for WSI Associates, and implementing robust verification processes, we’re not just protecting our business but also contributing to a more honest and efficient labor market.

Recent Cases and State Actions

Michigan has witnessed a range of UI fraud cases, emphasizing the need for constant vigilance. From individuals exploiting the identities of prison inmates to fraudulent activities involving state contractors, these cases underscore the varied and sophisticated nature of UI fraud. The state’s response, including the formation of a UI Fraud Response Team and updated directives, has been pivotal in combating these challenges.

Protecting Against Fraud

Our team stays ahead of the curve, using resources and directives available to protect against identity theft and other forms of fraud. This proactive stance not only shields our business but also ensures that our clients are not unduly burdened by fraudulent claims.

The fight against UI fraud is ongoing, and our Risk team at WSI Recruitment and Staffing remains committed to this cause. Through their diligence, we continue to foster a business environment that is both competitive and ethical, benefiting our clients and the broader community.

Reporting UI Fraud

Awareness and prompt reporting are key in fighting UI fraud. If you suspect fraudulent activities, it’s essential to report it immediately through the official channels. This proactive approach is a critical step in safeguarding the integrity of the unemployment insurance system.

Fraud or scam reports may be made to the Consumer Protection Division of the Michigan Attorney General’s office at 517-335-7632, toll free 1-877-765-8388, or online.

Thursday is the New Friday: The Four-Day Workweek is Coming

In the corporate world, particularly in manufacturing, the idea of a four-day workweek can seem as fanciful as a unicorn. But is it really? Let’s dive into this intriguing concept, particularly focusing on the manufacturing sector in America, a realm traditionally resistant to such radical changes due to its nature of work.

The four-day work week has gained traction globally, thanks in part to successful trials in various sectors, and is particularly appealing to younger workers who value a more employee-centered work environment. If forced to return to a five-day week, over 40% of workers indicated they would expect significant raises. This highlights the growing shift towards valuing work-life balance and mental health in the workforce, though the feasibility of a four-day workweek varies significantly across industries.

But manufacturing has been slow on the uptake. Why? The challenges are unique: the physical presence required, the continuous production cycles, and the lack of remote work options. Yet, as a staffing company that ensures our own employees strive to maintain a healthy work-life balance, we see potential in this model, even in our specialty field of manufacturing.

A case in point was made in a recent NPR article about Advanced RV, a luxury motorhome manufacturer in Ohio, which successfully adopted this model. Initially, there was skepticism. Workers like Bill Kowalcic wondered if they could maintain productivity. A year and a half later, the answer is a resounding yes. The key? Finding shortcuts and time savers without compromising quality.

The global trial, led by 4 Day Week Global, suggests that reducing hours while maintaining pay can lead to more energy and efficiency in the workplace. This isn’t about doing less; it’s about maximizing productivity within a compressed timeframe. Advanced RV’s journey illustrates that even in the realm of manufacturing, where the stakes are high and the work physically demanding, this model can work.

The initiative’s success hinges on several factors: a willingness to take risks, trust in the workforce, creativity, and open-mindedness. CEO Mike Neundorfer’s decision to shift to a 32-hour week without pay cuts was a gamble, but it paid off. The company has nearly recovered the initial dip in productivity and has seen a boost in employee satisfaction.

But how does this apply to the wider manufacturing sector, especially larger, more traditional firms? It requires a radical rethinking of operations. We must ask: Are there tools or processes that can be optimized? Can we redistribute tasks based on speed and skill, thereby enhancing efficiency?

The biggest hurdle, however, is cultural. In an industry that often values time spent on the floor over actual output, shifting mindsets is crucial. It’s about quality over quantity and results over hours. This shift can lead to a more motivated, focused workforce, reducing burnout and improving overall well-being.

For larger manufacturers, this might mean a phased approach, perhaps starting with one department or a pilot group. It’s about measuring productivity in outcomes, not hours. The focus should be on what gets done, not how long it takes to do it. Some have taken to four ten-hour workdays, and bringing in a weekend crew to run three days of twelve-hour shifts on Friday, Saturday, and Sunday.

An article earlier this year highlighted a manufacturing company that had previously tried a four-day workweek a decade ago without success. However, they revisited the idea due to requests from their deskless workers. The management considered shifting to four 10-hour shifts per week, with employees working either Monday to Thursday or Tuesday to Friday. However, several challenges arose:

- Unpopularity of Tuesday-Friday Shifts: No one wanted the Tuesday to Friday shift, but the company needed Friday coverage as they ship products five days a week.

- Shift Overlap and Equipment Limitations: The day and night shifts overlapped by 10 minutes, and there wasn’t enough equipment to extend shifts by two hours.

- Overtime and Safety Concerns: Extending workdays to 10 hours raised safety concerns due to the physical nature of the job. The company was particularly worried about safety in the additional hours, as the work is physically demanding.

After two months, the company, O.C. Tanner, reverted to its previous system. Despite the unsuccessful attempt, the effort demonstrated to workers that the company valued their input and was willing to explore new work arrangements. This approach underscored the company’s willingness to innovate and adapt, key elements in fostering a positive company culture.

A six-month pilot program in the U.S. and Ireland showed promising results for most companies, with 90% not wanting to return to a five-day week. Despite these benefits, which include improved worker health and productivity, some industries, like manufacturing and service, face unique challenges.

American Plastic Toys Inc. tried the four-day workweek by extending work hours across four days but found a decline in productivity beyond the standard 7.5 to 8-hour shift. Company President John Gessert noted the approach led to a net loss in activity per hour and was physically taxing for employees. The need to ship products five days a week and maintain equipment operations in their factories further complicated the transition.

CEO of Dickey’s Barbecue Pit, Laura Rea Dickey pointed out the difficulty of adopting such a schedule amidst staffing shortages and the need for maximized productivity. In such industries, reducing work days can lead to income loss for staff dependent on tips. Some restaurants however, aren’t going to go down that road at all, simply eliminating the human element.

Daniel Hamermesh, professor emeritus of economics at the University of Texas and author of a new study about the rise of the four-day workweek, argues that workers are not 100% productive during each minute of the workday anyway and that there are very few jobs where workers can produce the same amount in total while working 20% less. “If a 32-hour week were widespread, the U.S. would produce less, would have lower GDP, and lower living standards,” Hamermesh told FOX Business. “No problem, if people want more leisure and are willing to forego some income. But we can’t have more leisure time—less work—and keep the same income. We can’t get something for nothing.”

Changing to a four-day workweek isn’t going to be easy, and it’s going to shake things up a bit economically. But let’s face it – manufacturing has got to figure this out. The inevitability of this shift is underscored by the preferences of the younger workforce; without a meaningful work-life balance, we risk seeing a mass exodus from the manufacturing sector in the coming years. As we stand at this crossroads, it’s essential to recognize that adapting to a shorter workweek could be the key to sustaining our industry’s future. They want a life outside of work, and who can blame them? So, maybe it’s time we seriously consider making Thursday the new Friday. It’s not just a catchy phrase; it could be what keeps our factories humming with happy, motivated workers in the years to come.

Resilient Labor Force in Changing Times: An Opportunity for Employers

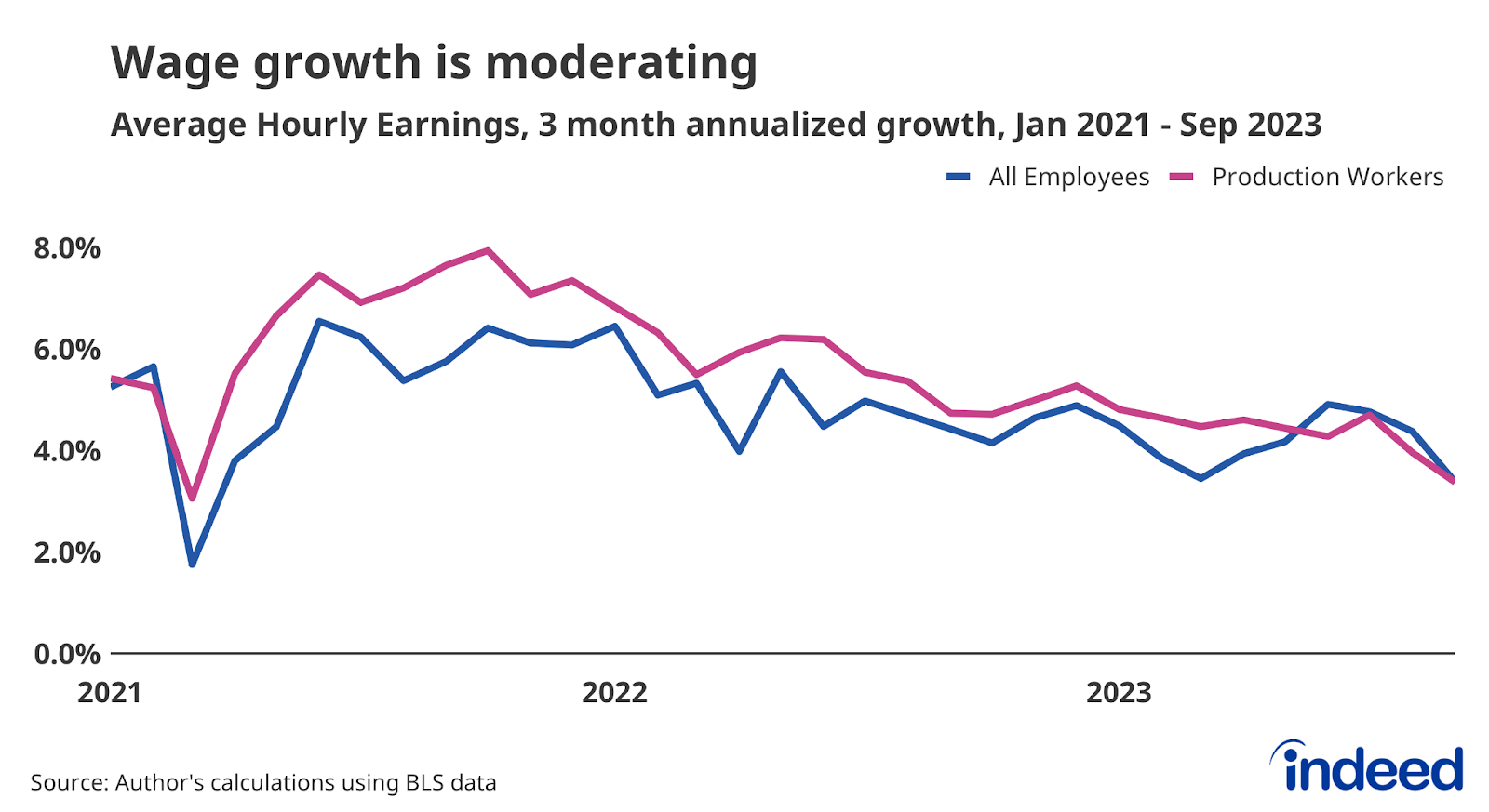

As wages stabilize, employers should take note that labor negotiations and their impact are actually presenting a golden opportunity to increase their labor force.

Continue readingLabor’s Leverage: Workers Have Started Something

The US labor market, particularly in the manufacturing sector, has witnessed significant shifts in recent times. As of September 2023, the manufacturing landscape is marked by a unique juxtaposition of elevated job postings and wage growth, albeit at a decelerating pace compared to national averages.

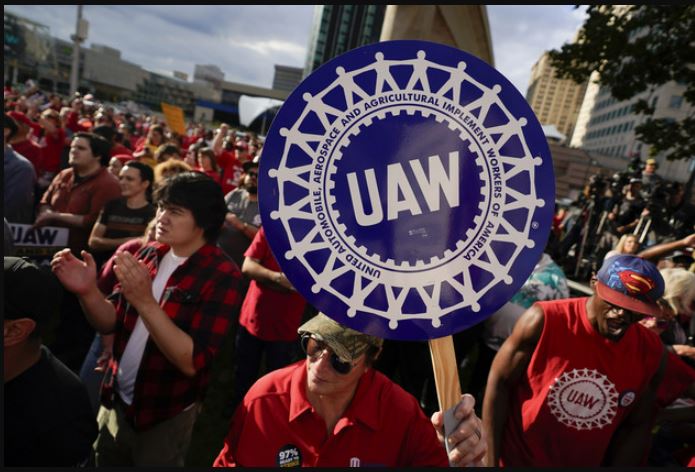

Manufacturing workers, after enduring decades of sluggish wage growth, are now making their voices heard. The headline that captures the essence of this movement is the United Auto Workers (UAW) strike that began last month. The UAW and the Detroit Three automakers are inching closer to a deal. The public statements and postures might paint a picture of discord, but behind the scenes, progress is evident, especially with Ford and Stellantis. GM’s recent acquisition of a $6 Billion line of credit flashes signs that they are digging in. The strike is costing GM about $10 million per day. Which isn’t great. But not as bad as some predicted. The costs could stretch into Billions of dollars if the strike persists into November.

The UAW’s demands are clear: job and income security, increased compensation, pay equity, work-life balance, and the inclusion of planned electric vehicle production under the union’s national master contracts. The Big Three’s proposals have largely responded to the union’s demands, with considerations for their performance-related metrics. Since the strike began on September 15th, it’s estimated cost is around

Analysts estimate that the full cost of the union’s demands would more than double the average hourly labor costs of the companies. Investors are wary of such a steep increase, fearing a return to the financial instability of the past.

Ford and Stellantis have made significant offers to narrow the gap on key items. GM, however, remains a point of contention. The path to a final settlement requires flexibility, give-and-take, and a focus on common interests. Despite the fiery rhetoric, compromise remains possible.

However, it’s not just the manufacturing sector that’s seeing labor unrest. Michigan’s largest retail chain, Meijer, is also in the spotlight. Tens of thousands of Meijer workers, represented by the United Food and Commercial Workers Local 951, are gearing up for union contract negotiations. Their demands? Wage increases, more paid time off, and an enhanced medical plan. The sentiment is clear: after risking their lives during the pandemic, these workers feel they deserve better compensation and benefits.

John Cakmakci, the president of the UFCW Local 951, poignantly remarked, “When the pandemic hit, we were all going to work. We seem to have been forgotten now.” He emphasized that it’s time for Meijer to share its “healthy profits” with its workforce.

This sentiment is echoed across various sectors. High-profile contract negotiations are underway, including those between the SAG-AFTRA actors and artists and Hollywood studios. Along with wins from the SAG Writers Guild, UPS, and The UAW’s pressure tactics on Detroit’s Big Three, Organized Labor could be starting to have it’s moment and strengthening it’s appeal, especially as Gen-Z becomes the largest part of the workforce over the next few years.

Interestingly, the pendulum seems to be swinging rapidly towards labor. As Cakmakci noted, in his 40 years of experience, he’s never witnessed such a swift shift. This sentiment is backed by data from the Economic Policy Institute, which found that union membership in the US increased by more than 16 million workers from 2021 to 2022. However, a closer look reveals a nuanced picture: while more jobs were unionized, nonunion jobs were added at a faster rate, causing a slight decline in the share of workers represented by a union.

On October 4, 2023, over 75,000 unionized employees of Kaiser Permanente, a leading not-for-profit health provider in the US, initiated the largest healthcare worker strike in the country’s history. The workers, spread across states like California, Colorado, and Washington, are protesting for improved working conditions, especially in the aftermath of the pandemic. Their demands include better staffing levels, citing current shortages that jeopardize patient care and push many to their limits. The strike, which began at 6 am, is expected to last until Saturday morning. If no agreement is reached, a more extended strike might occur in November.

Despite these challenges, unions are doubling down on their efforts. They’re leveraging public support, which is near an all-time high, and the growing outrage against skyrocketing executive compensations to negotiate better deals. The willingness to strike, as demonstrated by the UFCW’s demands for “significant wage increases” and better medical plans, underscores the changing dynamics.

The labor landscape in the US, especially in Michigan, is undergoing a transformation. From manufacturing to retail, workers are demanding their rightful share of the pie. As negotiations unfold and strikes loom, one thing is clear: the voice of the worker is louder and more potent than ever before.

Ford Pauses Marshall EV Plant: Six Signs It’s Only Temporary

Ford’s $3.5 billion EV battery plant in Marshall faces uncertainty amid the UAW strike. Despite the recently announced pause, Michigan’s manufacturing industry remains resilient, boasting a skilled workforce, innovation, and a commitment to securing its place in the electric vehicle revolution. Confidence in the state’s future endures.

Continue readingUAW Strike: An Ace up the Big 3’s Sleeve

What ace does the Big 3 have up their sleeve to leverage their negotiations? Read our blog to see a quiet threat to Michigan’s economy that could play into the strike.

Continue readingSix Consequences of the UAW Strike

From the historic Flint Sit-Down Strike of 1936 to the recent 2019 showdown with General Motors, explore the legacy of UAW strikes and discover how today’s strikes are shaping the future of labor relations amid the electric vehicle revolution.

Continue reading